SLS, MJF, and FDM Post Processing – AMT

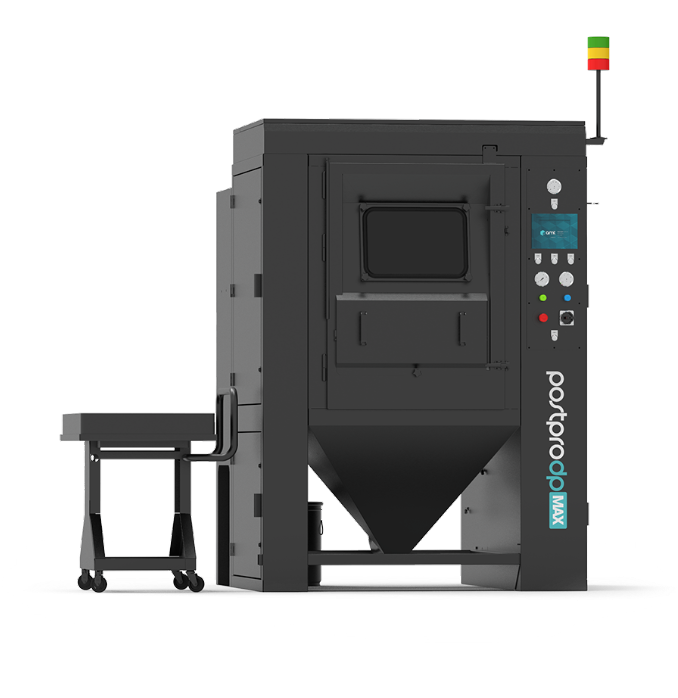

Through PostPro’s chemical vapor smoothing process, 3D printed polymer parts are now able to have a smooth finish with the help of fully automated surface finishing technology. This process improves part quality and integrity, as it is non-line-of-sight. Eliminating risks associated with production time, even for parts with complex geometries. RP America proudly carries the PostPro SF100 and the PostPro SF50, which means any application from prototyping to full production parts can be taken to the next level!

See Vapor Smoothing in Action

See our other post-processing equipment

Request a Quote

Want more information about the post-processing equipment that RP America carries? Let us know which equipment you have questions about and our sales team will be in touch!