Eplus3D (SLM)

RP America’s strategic alliance with Eplus3D unlocks a new dimension of additive manufacturing capabilities for our customers. By combining Eplus3D’s cutting-edge technology with RP America’s unparalleled service and support, we deliver comprehensive solutions that drive innovation and efficiency.

Eplus3D’s expertise in metal additive manufacturing is a game-changer. Their advanced metal AM systems offer exceptional precision, build quality, and material compatibility.

When combined with RP America’s comprehensive support, you gain access to a powerful partnership that accelerates your metal part production and delivers superior results.

Products and Services

Invest with confidence knowing that RP America is committed to your success. Our partnership with Eplus3D empowers you to harness the full potential of metal additive manufacturing and gain a competitive edge.

Eplus3D carries a full line of machines, including the EP-M2050, EP-M825, EP-M1550, EP-M1250, EP-M450H, EP-M650, EP-M450, EP-M400S, EP-M400, EP-M300, EP-M260, EP-M150, and EP-M150Pro. The EP-M400S and EP-M300 models are highlighted below.

AS A DIRECT SUPPLIER, RP AMERICA CAN MITIGATE SUPPLY CHAIN RISKS AND MINIMIZE THE CHANCE OF QUALITY ISSUES, RETURNS, OR INVENTORY DISRUPTIONS.

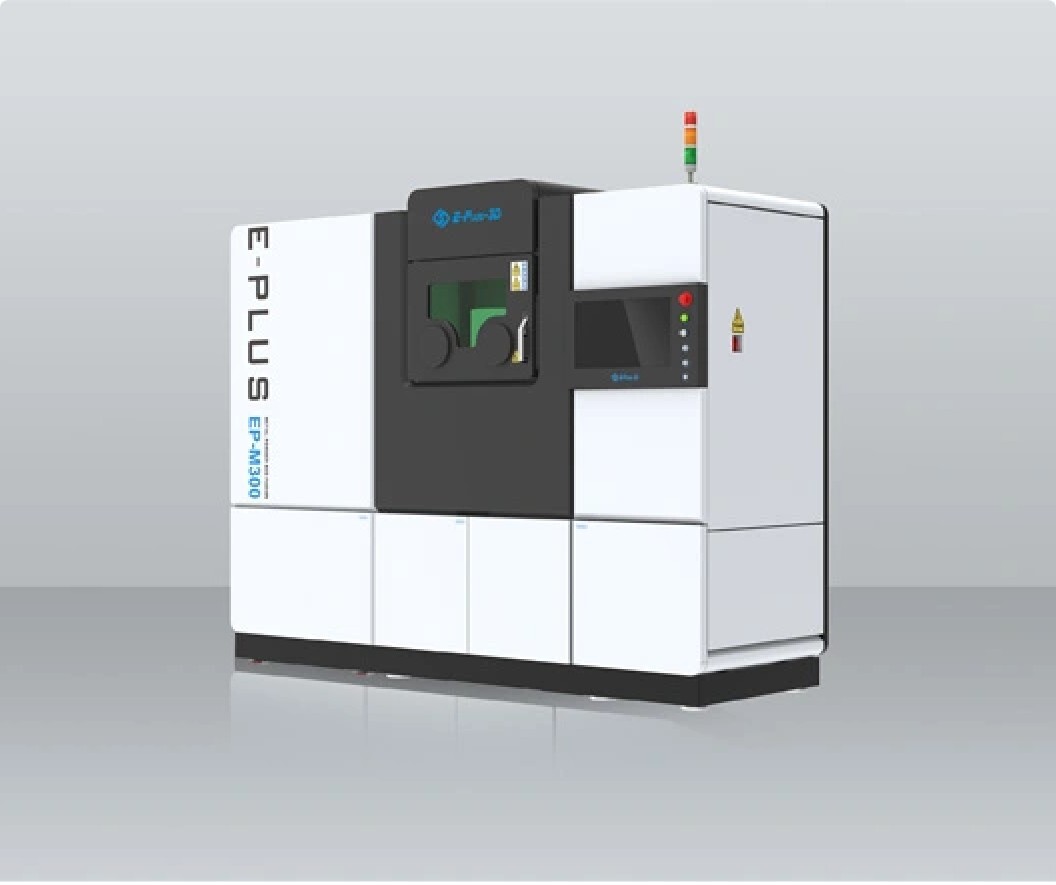

EP-M300

Consistent Performance

Innovative gas flow management, an optimized filter system, and superior sealing create a stable build environment with precise oxygen control, while precise laser beam quality control ensures optimal results.

High Productivity

Dual-laser technology enables non-stop operation during filter changes, while an optimized recoating strategy accelerates the build process within a spacious 300x300x450mm build volume.

Reliable and Easy Operation

Convenient powder recycling systems and a glove box structure minimize powder contact while intelligent software reduces human intervention and real-time monitoring optimizes the production environment and build process.

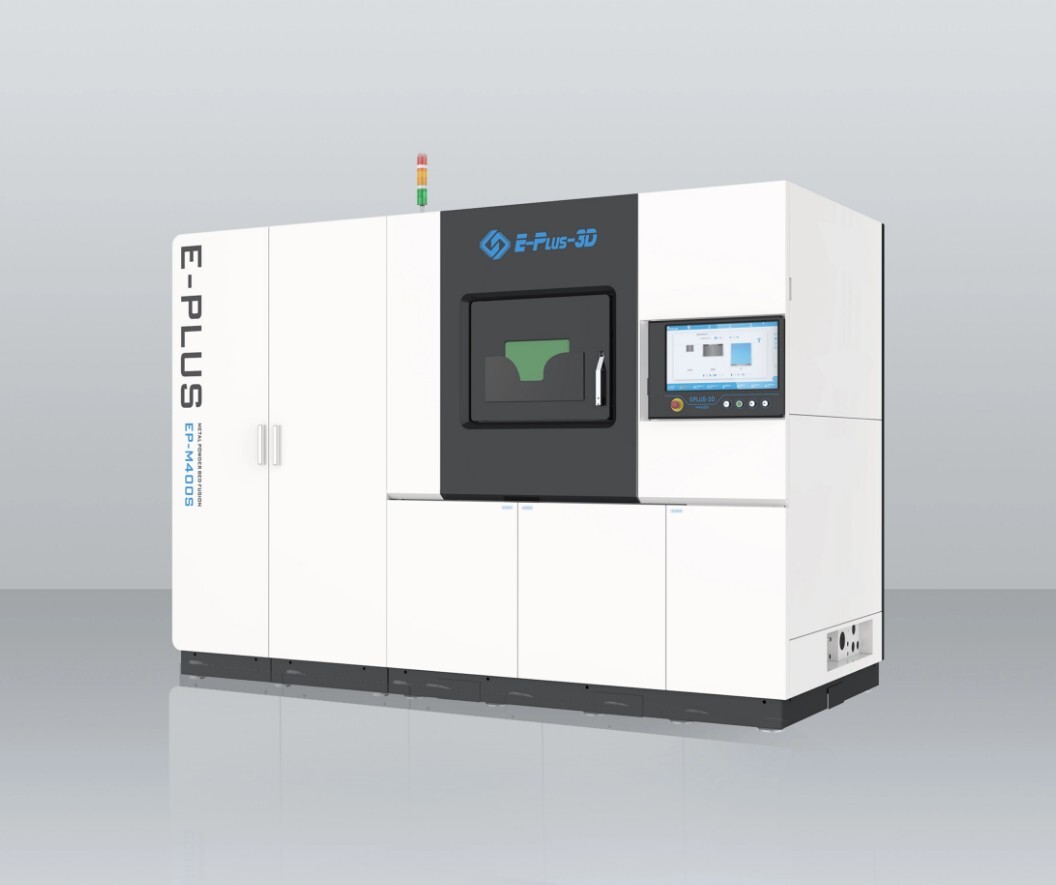

EP-M400S

Simplified Operation and Monitoring

A user-friendly interface with fully automatic one-click printing and pickup function allows for real-time monitoring of build job information with traceable printing parameters.

Enhanced Build Environment and Laser Stability

A three-stage filtration system with blow-back fume removal and a permanent filter, combined with stable laser output and energy control, minimizes defects. Optimized gas flow ensures clean parts.

Enhanced Safety and Compliance

Advanced monitoring, safety features, and rigorous certifications safeguard operators and the environment. Real-time checks of the working environment and air supply ensure reliable operation. The airtight system protects powder integrity and minimizes contamination risks.

Customer Testimonials

Accurate

Better accuracy than parts we were buying from a service bureau.

Productive

Best 3D printer I’ve ever owned.

Reliable

Zero failures in months of production.

Versatile

The ability to run multiple materials and quickly change is awesome.

Affordable

The machine paid for itself in 90 days.

Request a Quote

Want more information about our 3D printers? Let us know which equipment you’re interested in!