Industrial Stereolithography (SLA) 3D Printers

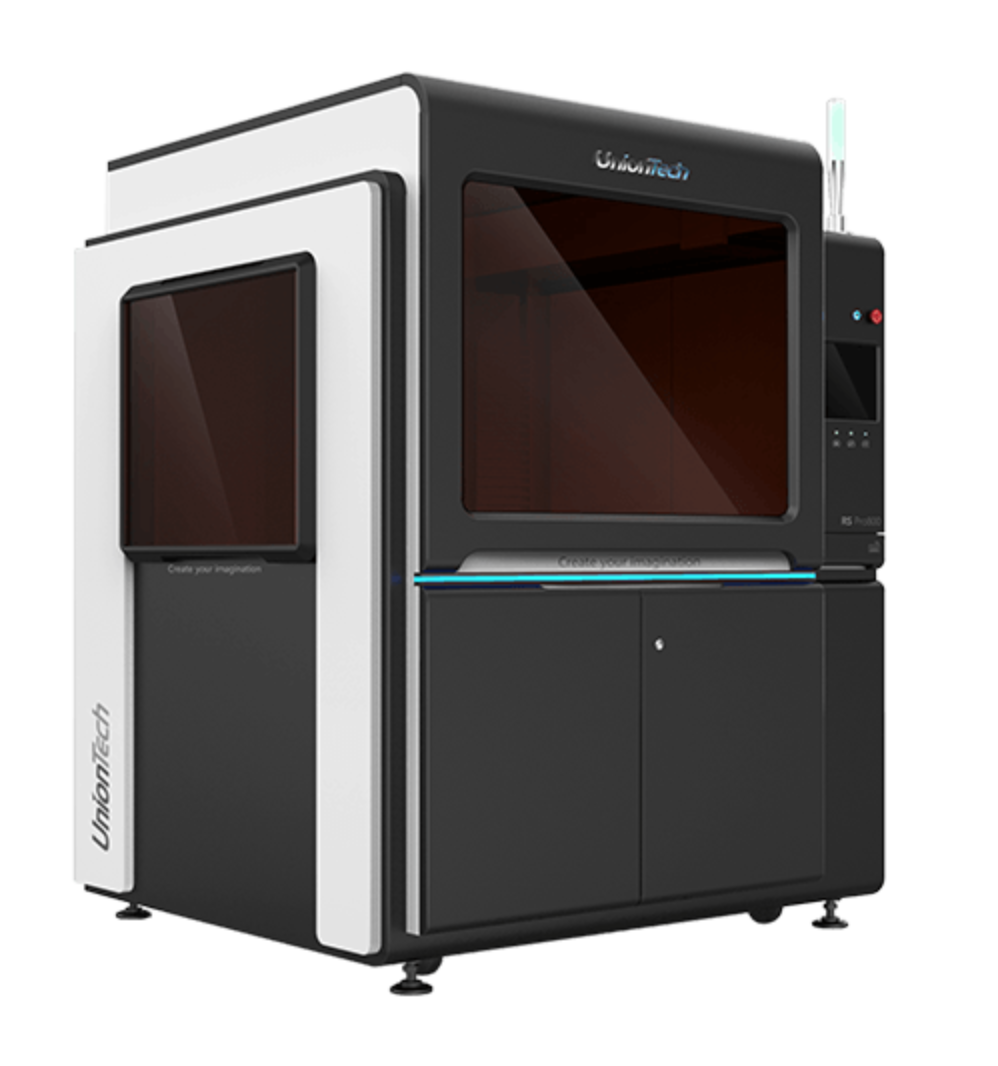

UnionTech RSPRO 800

UnionTech’s line of industrial 3D printing equipment brings a fresh dimension to stereolithography. The machines offer an open machine design that allows you to use the type of material you need, while superior part quality creates ultra-smooth surfaces and fine details. The products also deliver cost-effective solutions throughout the entire equipment lifecycle.

Features

Scanning speed can reach 15 m/s.

The scanning speed of the RSPro 800 is impressively fast, reaching an incredible rate of 15 meters per second. This exceptional scanning speed significantly reduces the overall time required for scanning operations. With such a high-speed capability, projects can b e completed in a fraction of the time it would take with slower scanning systems.

Key components are of international top brands.

Our machine is equipped with key components sourced from internationally renowned top brands. The selection process for these components was meticulous, ensuring that only the highest quality and most reliable options were chosen. Among these esteemed brands are Panasonic from Japan, Optowave from America, and Scanlab from Germany.

Automatic control of surface level and processing parameters.

With the automatic surface level control, The RSPro 800 intelligently detects and adjusts the surface level of the material being processed. This eliminates the need for manual adjustments and minimizes the chances of errors or inconsistencies. By maintaining an optimal surface level throughout the printing or processing operation, we can achieve exceptional precision and accuracy, resulting in flawless end products.

Marble recoating platform frame

The use of a marble recoating platform frame provides significant advantages. Marble’s hardness and dimensional stability offer a solid foundation, minimizing vibrations and enabling precise layer deposition. This ensures impeccable surface quality. Additionally, the marble frame allows for an impressive layer thickness of 0.05 mm, delivering accurate reproduction of intricate details.

Closed loop control strategy for: Platform movement/Laser power/Resin level resin temperature/Negative pressure

This dynamic control mechanism continuously monitors and adjusts these parameters in real-time, ensuring precise and consistent performance throughout the printing process. By actively regulating platform movement, laser power, resin level, resin temperature, and negative pressure, our machine achieves exceptional accuracy, reliability, and quality in the final printed objects.

CE certification

By achieving CE certification, the RSPro 800 demonstrates its compliance with the stringent regulations and quality standards set forth by the EU, ensuring that it meets the necessary criteria for safe and reliable operation.

RAPLAS PR 700

This machine provides a wide range of 3D printing capabilities: form and function prototyping and modeling, short-run injection molds, pattern creation, and investment casting.

Features

Solid State Laser

Equipped with a 1 or 2W air-cooled laser system, the RAPLAS 700 delivers superior stability and power throughout each print. They also provide dynamic focusing capabilities for industry-leading speed and part quality.

HD+ Scanning u0026 Resolution

The RAPLAS 700 provides industry-leading dynamic, three-axis scanning and dynamic focusing powered by the SCANLAB IntelliSCAN Scanning System. This offers the ability to increase scanning speed and enhance accuracy, repeatability, and resolution.

Intuitive Machine Interface

The RAPLAS 700 is operated through an intuitive LCD touchscreen interface. Combined with RAPLAS’ INTEGRA Plus processing software, this delivers robust, yet user-friendly machine operation capabilities.

Open Source Platform

The RAPLAS 700 is capable of printing in any certified 355nm resin. In conjunction with customized vat sizes with Z heights from 55 to 500mm, this provides users with options for flexible and hassle-free material changes.

Rigid Frame Construction

The RAPLAS 700 is built with a granite frame, which sets the standard for stability and precision. This provides excellent repeatability, accuracy, and thermal stability.

Large Access Doors

The wide opening doors of the RAPLAS 700 allow for easy removal of build platforms, saving time and effort. Along with the stainless steel rim cover, this allows for easy clean-up upon completion of your print.

Customer Testimonials

Accurate

Better accuracy than parts we were buying from a service bureau.

Productive

Best 3D printer I’ve ever owned!

Reliable

Zero failures in months of production.

Versatile

The ability to run multiple materials and quickly change is awesome!

Affordable

The machine paid for itself in 90 days.

Request a Quote

Want more information about our 3D printers? Let us know which equipment you’re interested in!